Visual and Audible Oxygen Alarms:

The OX-600 displays Oxygen (O2) levels on an LCD screen that changes colour at each alarm level. This is a unique feature of the Riken Keiki 600 series.

The Unit comes with preset alarms set to Low and Low Low . Users can program their own alarm levels if desired. Users can access relay outputs for 1st and 2nd alarms in addition to a 4-20mA output. These features allow customers to connected optional external accessories such as additional sounders and beacons.

The Instrument comes ready to operate with a 24 VDC Power supply as well as a Battery Powered option. An optional 240VAC Main adapter is available.

Sensor Technologies :

The OX-600 has a low-cost galvanic Oxygen(O2) sensor, in addition customers can replace the sensor in the field without the need for special tools.

The sensor has a pressure compensation feature to avoid false alarms.

Remote Oxygen ( O2 ) Sensor:

As an option the OX-600 has an extender cable that allows the unit to be mounted outside the room with the sensor inside. Staff have the ability to ascertain the state of the room prior to entry as a result.

Optional accessories are available. These include a Battery backed UPS (WPSU-24 Series ) in addition to a sounder beacon(s) (Accessories) .

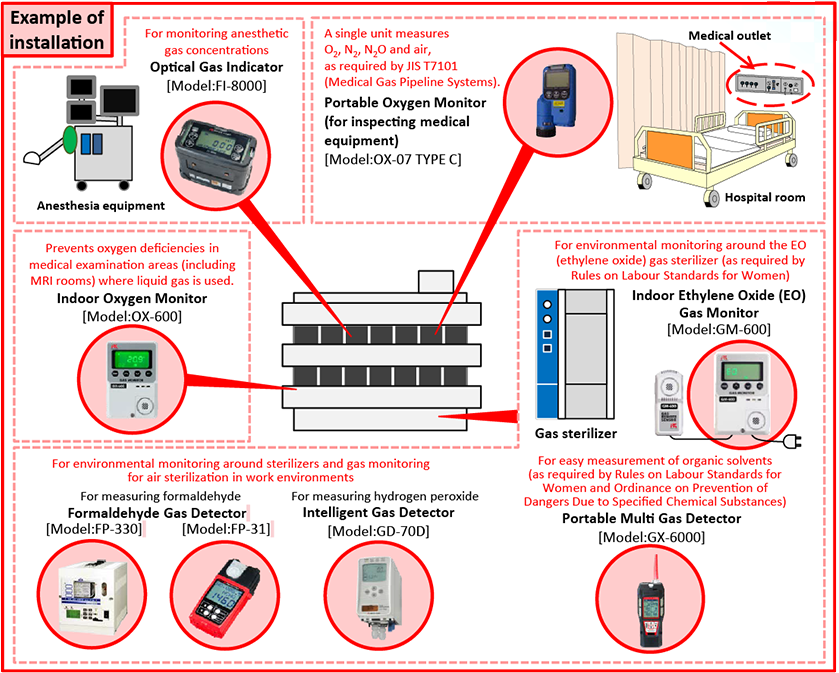

Typical OX-600 Applications are Laboratories , Hospitals , Gas Storage rooms , Clean rooms in addition to Cryogenics storage facilities and Warehouses

The OX-600 is a member of the 600 series of standalone monitors in addition this family includes OX-600, RI-600, EC-600, GM-600