These Boiler rooms ( also known as Mechanical rooms ) house HVAC ( Heating , Ventilation , Air -conditioning ) systems. These systems are large and complex and require trained technicians to manage and operate them. It is important therefore to protect the health and safety of these technicians and other personal.

A major component of the HVAC system is the water heater or Boiler . Heat generated from natural gas is managed through a complex maze of pipes and switches known as the gas train . It is the gas train that safely feeds natural gas into the burner.

With such equipment operating continuously, Methane, Carbon monoxide and in some applications, Carbon Dioxide have the potential to leak into the atmosphere. This can constitute a serious health risk to staff . Boilers located in enclosed or confined spaces pose a higher risk as it is easier for the gas to accumulate.

Combustible Gas Risk In Boiler Rooms:

Natural gas ( Mainly Methane ) expands rapidly and is lighter than air it therefore rises to the roof space in a boiler room.

Many gases such as natural gas, methane are flammable within a range of concentration known as the explosive or flammable range.

This range is defined by the lower explosive limit (LEL) and upper explosive limit (UEL) and differs for each flammable gas. At concentrations below the LEL, the mixture is too lean (insufficient fuel with respect to oxygen) to sustain combustion, and at concentrations above the UEL, the mixture is too rich (too much fuel with respect to oxygen) to sustain combustion.

It is therefore important to be able to detect Natural gas levels in the Boiler room to ensure they stay below LEL Levels

Carbon Monoxide Gas Risk In Boiler Rooms:

Carbon Monoxide (CO) is a poisonous gas that is produced by the incomplete burning of fossil fuels, including natural gas which is often used in modern industrial Boiler Rooms.

CO has no odour, colour or taste therefore people may not realise they are being exposed.

Maintenance Personnel working in Boiler Rooms are vulnerable to CO poisoning which can and often does prove fatal.

With the increasing focus on health and safety there are increasing calls to install Carbon Monoxide Monitors in Boiler rooms. It is important to not just detect CO but to monitor levels of this potentially lethal gas.

Image Courtesy of P199 at English Wikipedia

The Solutions :

RM-5000 2-12 channel monitoring panel with EC-600 ( CO ) and GD-A80 ( Methane ) detectors ( Also CO2 in some cases )

The RM-5000 is ideal for monitoring combustible gases, oxygen, and toxic gases. It is ideal for use in medium to large Boiler rooms

The RM-5000's clever modular design allows for monitoring of 2 to 12 channels. The RM-5000 achieves this by simply by inserting indicator units to match the gas required. In addition a custom panel will accommodate up to 32 Channels. The modular indicator units slot into the case. Users then connect detector heads for Carbon Monoxide and Combustible gases such as Methane among others. Due to the cost sensitive nature of Boiler room applications the use of simple monitors and detector heads is ideal. We recommend the EC-600 for CO and GD-A80 for Methane .

The Indicator units each have an independent digital display that is easy to read . Each Indicator has a bar meter and multi-colour display for ease of monitoring. Power consumption is very low.

RM-5000 Connect to building Management Systems :

An Alarm unit is fitted as standard. Most importantly a 4-20mA and RS-485 outputs are available. These outputs allows the RM-5000 to connect to external PLC's and Building management systems . This allows Users to monitor every channel and data-log the results. This is a very useful feature. The RM-5000 is 24VDC powered so therefore can be used with the BATPSU-600 battery backed Power supply to ensure continuous operation even in the event of a power failure . A 240VAC version also available as an option .

Remote Sounder beacons connected to the RM-5000 provide additional warnings in remote rooms and areas.

The RM-5000 is extremely Robust and more importantly reliable making it ideal for use in Industrial HVAC applications.

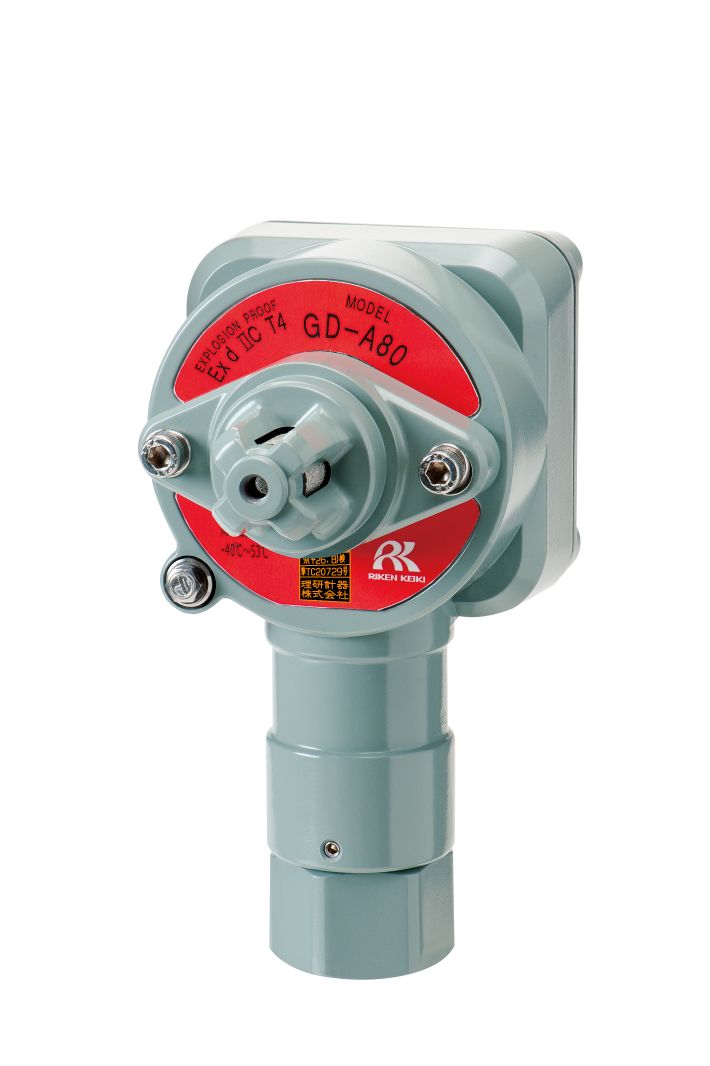

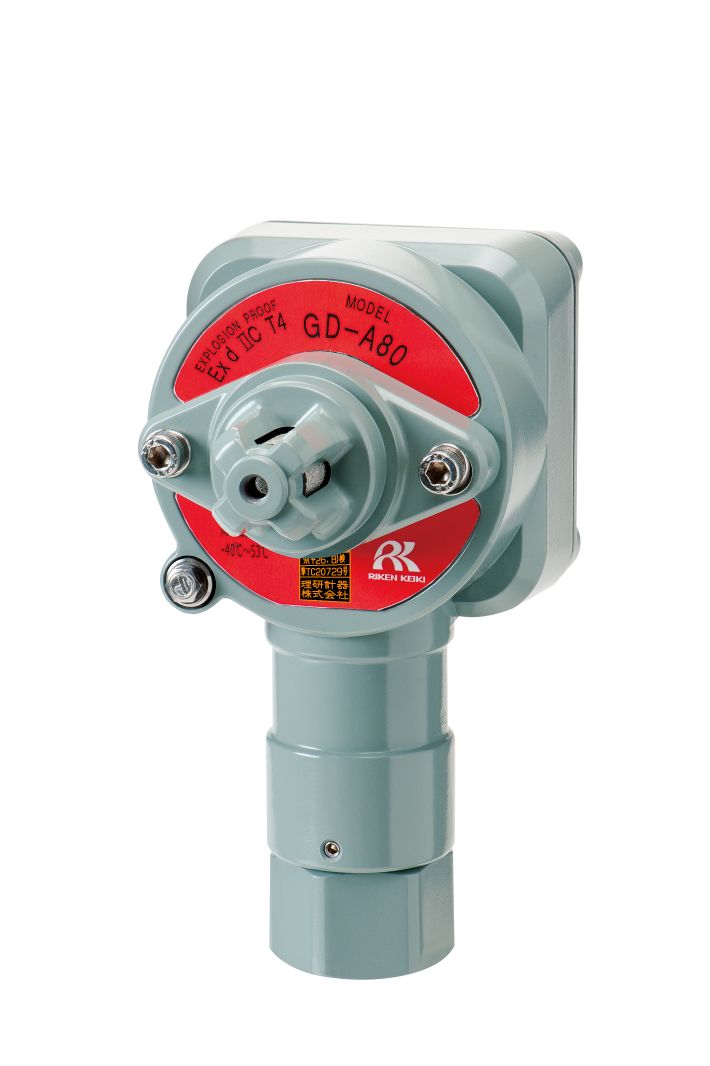

Detector Heads : Methane

The GD-A80 is a rugged gas detector head for Combustible gases it can be remotely mounted close to the boilers to detect leaks in natural gas . The GD-A80 is Explosion proof and ATEX approved for use in hazardous environments making it ideal for HVAC applications.

Detector Heads : Carbon Monoxide

The EC-600 is a Carbon Monoxide monitor. The EC-600 comes with preset alarms set to High and High High. Users can program their own alarm levels if desired. Users can access relay outputs for 1st and 2nd alarms in addition to a 4-20mA output. This output can be used to connect the EC-600 to the RM-5000 monitor panel .

Detector Heads : Carbon Dioxide

If the fuel in the boilers is organic ie wood or Biomass etc then Carbon Dioxide is also produced . if you breathe high concentrations of carbon dioxide you may be at risk for carbon dioxide intoxication or even Carbon Dioxide Poisoning. Carbon dioxide intoxication and Carbon Dioxide poisoning are independent of oxygen concentration, so you may have enough oxygen present to support life, yet still suffer from the effects of rising carbon dioxide concentration in your blood and tissues.

The condition of excess carbon dioxide concentration in the blood is called hypercapnia or hypercarbia. Symptoms of carbon dioxide toxicity include high blood pressure, flushed skin, headache and twitching muscles. At higher levels, you could experience panic, irregular heartbeat, hallucinations, vomited and potentially unconsciousness or even death.

The RI-600 is a Carbon Dioxide Enrichment Monitor. It can be used to Monitor Carbon Dioxide levels and can also be connected to the RM-5000.

The RI-600 has preset alarms set to High and High High. Users can program their own alarm levels if desired. Users can access relay outputs for 1st and 2nd alarms in addition to a 4-20mA output. These features allow customers to connect optional external accessories such as such as additional sounders and beacons.

Additional Optional Accessories include additional remote sounders and beacons, Battery back up and Autodiallers . The system can also control ventilation fans and shutoff valves if required.